- HOME

- Products

- Basic materials

- Technical conditions

- Technological equipment

- CAD CAM

- The Laser Photoplotter

- CNC drilling and routing

- UV Laser drilling and routing

- Laser Tannlin TX PROi

- Direct plating

- Vyplňování otvorů | Planarizer

- Surface readjustments

- Surface finishes

- Galvanic processes

- Digital Direct Imaging

- The etching

- Solder mask and silkscreen

- Inspections of PCB

- Controlled impedance

- Multilayer lamination

- Contour fabrication

- Analytical Laboratory

- PCB Designs

- PCB assembly

- Terms and Conditions

- Preislist

- Contact

- kariéra

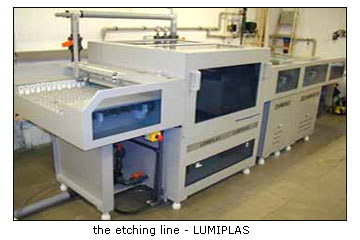

The etching

A perfect etching of DPS depends primarily on the correct chemical composition of the etching bath and subsequent rinsing of the residual etchant. The etching line LUMIPLAS is fitted with automated measuring of temperature, density of the bath and its pH. Drain of the saturated etchant and dosing of a new etchant take place automatically depending on the measured values. The conveyor makes it possible to set an optimal speed and its technology is adapted even to very thin materials. Behind the etching module there is a rinse by clean etchant and perfect wash of boards is ensured by 3-level water cascade.

company adress :

company adress : place of business :

place of business :