- HOME

- Products

- Basic materials

- Technical conditions

- Technological equipment

- CAD CAM

- The Laser Photoplotter

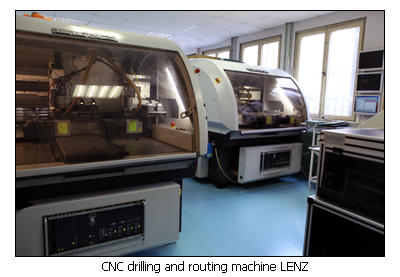

- CNC drilling and routing

- UV Laser drilling and routing

- Laser Tannlin TX PROi

- Direct plating

- Vyplňování otvorů | Planarizer

- Surface readjustments

- Surface finishes

- Galvanic processes

- Digital Direct Imaging

- The etching

- Solder mask and silkscreen

- Inspections of PCB

- Controlled impedance

- Multilayer lamination

- Contour fabrication

- Analytical Laboratory

- PCB Designs

- PCB assembly

- Terms and Conditions

- Preislist

- Contact

- kariéra

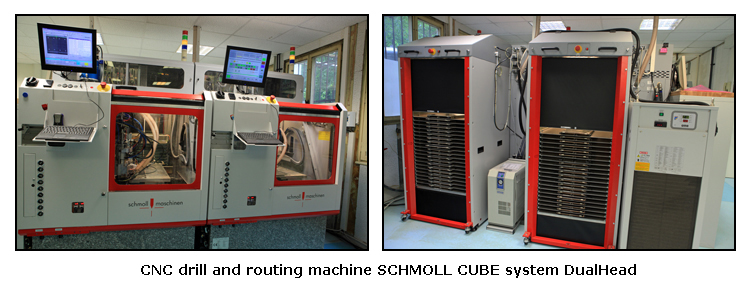

The drilling and routing machine

The technology of linear drives - instead of present rotary servomotors - influenced noticeably the construction of all devices with exact positioning. Today, linear engines are part of the majority of testers, coordinate drills and routers, automated imagesetters and many other machines. The LENZ DLG 550-2 AL is a two spindle drill with an automated loader. The use of linear drives together with massive granite base guarantees the precision of positioning to 3µm. Each spindle has an individually controlled Z axis and is provided with a tool holder for 528 tools. High-revolution spindles enable the use of drill bits from 0,1mm of diameter. The measuring device, being part of the drill, checks the diameter of the tool, the correct length and possible vibration amplitude after every change of the tool.

|

|

New linear drilling machine SCHMOLL CUBE with automatic loader is our new helper for drilling multilayer boards that needs to be optically registered. Its CCD camera assists us in registering all inner layers and we can later use its measurements for drilling blind vias. It has two heads - one for drilling and second one for milling. Therefore we can drill and mill all boards in only one machine without any needs to repack or reregister boards.

|

|

- accurate 2-spindles machine with automatic CCD camera for PCBs inner layers registration |

company adress :

company adress : place of business :

place of business :