- HOME

- Products

- Basic materials

- Technical conditions

- Technological equipment

- CAD CAM

- The Laser Photoplotter

- CNC drilling and routing

- UV Laser drilling and routing

- Laser Tannlin TX PROi

- Direct plating

- Vyplňování otvorů | Planarizer

- Surface readjustments

- Surface finishes

- Galvanic processes

- Digital Direct Imaging

- The etching

- Solder mask and silkscreen

- Inspections of PCB

- Controlled impedance

- Multilayer lamination

- Contour fabrication

- Analytical Laboratory

- PCB Designs

- PCB assembly

- Terms and Conditions

- Preislist

- Contact

- kariéra

Technology LASER cutting

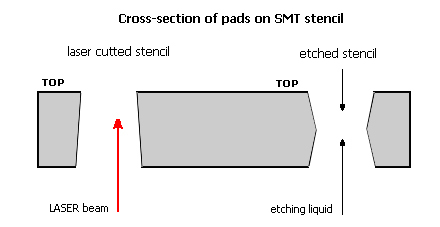

Increasing demands on the functionality of electronic products, along with the ongoing miniaturization of components bring new demands also on PCB manufacturing and assembly. Shrinking of semiconductors and other passive components bring problems with accuracy of seating components on board and also in solder paste printing. Printing solder paste on SMD pads is usually done via a metal stencil with holes created by different technologies. In the past, stencils were made by etching foil made from Alpaca. This time-proven technology was used for many years. It was reasonably accurate for customers and economically viable for producers, which were generally PCB manufacturers. With the increasing number of BGA and microBGA components, this technology has reached its technological. Compliance with the tolerances of etched holes and shape of etched edges do not provide reliable and uniform application of the paste to the micro pads. For these reasons, the qualified assembly companies gradually transfer their assebmly lines to the laser cutted SMT stencils produced from high-quality stainless steel foil.

To ensure better operability of SMD assembly companies, PragoBoard company has decided to purchase equipment for laser cutting of SMT stencils. The goal was to build a site capable of delivering the required high quality SMT stencils and to be ready to respond to the needs of customers needs. We are building on the knowledge of data formats used in the PCB design and also on understanding of customers needs and requirements. When selecting a machine, we had in mind just our customers requirements, thus ensuring the dimensional accuracy and compliance with continuous taper angle. Our choice was LaserCut III device, which meets all the demands of choice. Currently, we are operating second, more modern LASER Tannlin PROi TX. Its advantage is not only speed, accuracy and purity of cutting, but also the camera that controls cutted pads and in case of any mistake automatically recuts them.

For SMT stencil laser cutter are most important these criterias :

1. Dimensions of cutted area

2. Speed of cutting / Number of cutted pads per hour

3. Laser positioning accuracy and repeatabilityof the position

4. Taper angle ( angle of the edge )

|

|

While the first two parameters are important for manufacturers and provide a manufacturing efectiveness, others are relevant for the users – mostly assembly companies. Especially the last parameter requires special attention. This is the angle of the cutted edges, which ensures smooth and repeatable separation of the paste from the stencil and thus multiple printing without any needs for cleaning. Stable compliance of this angle on whole area of the stencil is still not commonplace for all machines and can affect the quality of the stencil, and thus assembling of printed circuit boards.

company adress :

company adress : place of business :

place of business :