- HOME

- Products

- Basic materials

- Technical conditions

- Technological equipment

- CAD CAM

- The Laser Photoplotter

- CNC drilling and routing

- UV Laser drilling and routing

- Laser Tannlin TX PROi

- Direct plating

- Vyplňování otvorů | Planarizer

- Surface readjustments

- Surface finishes

- Galvanic processes

- Digital Direct Imaging

- The etching

- Solder mask and silkscreen

- Inspections of PCB

- Controlled impedance

- Multilayer lamination

- Contour fabrication

- Analytical Laboratory

- PCB Designs

- PCB assembly

- Terms and Conditions

- Preislist

- Contact

- kariéra

Galvanic processes

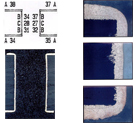

Fully automatic galvanic line was made-to-measure for production of PCBs in our company. It is equipped with two independent loaders and separate loading and stacking part. Each bath is controlled by pulse-power supply, which guarantees steady metal plating of both surface and holes. Control program sets up time and current of bathing exactly by surface of each board. Cross sections of our PCBs showed that metal plating is steady in whole area and have minimal solid thickness 20µm.

company adress :

company adress : place of business :

place of business :