- HOME

- Products

- Basic materials

- Technical conditions

- Technological equipment

- CAD CAM

- The Laser Photoplotter

- CNC drilling and routing

- UV Laser drilling and routing

- Laser Tannlin TX PROi

- Direct plating

- Vyplňování otvorů | Planarizer

- Surface readjustments

- Surface finishes

- Galvanic processes

- Digital Direct Imaging

- The etching

- Solder mask and silkscreen

- Inspections of PCB

- Controlled impedance

- Multilayer lamination

- Contour fabrication

- Analytical Laboratory

- PCB Designs

- PCB assembly

- Terms and Conditions

- Preislist

- Contact

- kariéra

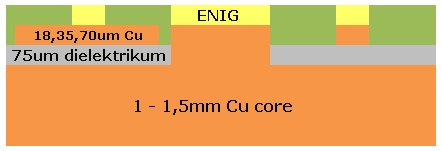

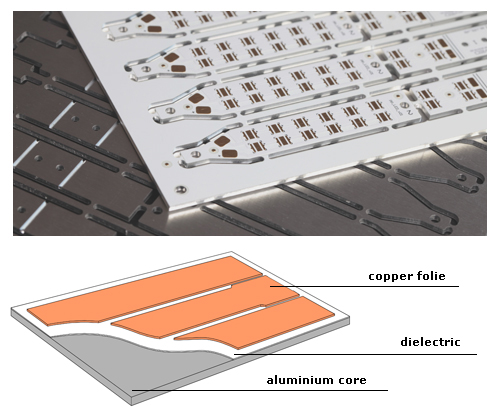

IMS - Insulated Metal Substrate PCB´s

The use of LED technology is increasingly popular for lighting applications in the automotive industry, in architecture or in interiors. IMS (Insulated Metal Substrate) is an excellent solution for electronic components with high heat generation at relatively low costs. The use of IMS technology allows LEDs to operate at lower temperatures, leading to improved energy efficiency, longer life and performance. A typical solution is an aluminum or copper based substrate with a thin dielectric material with high thermal conductivity and a copper foil on top. The products meet the highest requirements for thermal resistance and thermal conductivity. We offer both the production of standard single-sided IMS printed circuit boards and double-sided boards with a metal core. Our technology also enables the production of plated holes isolated from the metal core itself.

|

|

The best solution for LED applications with a demanding heat transfer profile is THERMALPAD (Pedestal Technology). The THERMALPAD design allows the designer to get a direct path between the LEDs (heat generator) to the metal core of the printed circuit board. This technology is used for applications where the heat dissipation of the LED component through the dielectric is not sufficient and thus only the direct heat path between the LED and the metal core of the PCB will allow sufficient cooling of the LED component. Due to its construction, copper is used as the metal core and not aluminum.

Base materials for production: http://www.pcb.cz/en/ims_material

company adress :

company adress : place of business :

place of business :