- HOME

- Products

- Basic materials

- Technical conditions

- Technological equipment

- CAD CAM

- The Laser Photoplotter

- CNC drilling and routing

- UV Laser drilling and routing

- Laser Tannlin TX PROi

- Direct plating

- Vyplňování otvorů | Planarizer

- Surface readjustments

- Surface finishes

- Galvanic processes

- Digital Direct Imaging

- The etching

- Solder mask and silkscreen

- Inspections of PCB

- Controlled impedance

- Multilayer lamination

- Contour fabrication

- Analytical Laboratory

- PCB Designs

- PCB assembly

- Terms and Conditions

- Preislist

- Contact

- kariéra

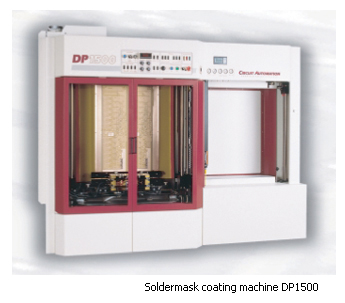

Solder mask and service print

Efforts to automate the production processes in the widest possible scale recently reflected in buying machine for automatic solder mask application. This technology ensures consistent quality of solder mask and also much better throughput.

|

|

|

In 2009 we installed two new exposure machines from American company OLEC. Lower demand on technological equipment forced many manufacturers to drop prices of their machines and therefore accelerated our decision to buy these exposure machines. OLEC AT30 is fully automatic exposure machine with 4 registration cameras. Speed and absolute accuracy of registration allows us to produce even the finest PCBs with BGAs. Second machine was installed as a solder mask exposure machine and we believe that this step will improve our quality even more.

company adress :

company adress : place of business :

place of business :