- HOME

- Products

- Basic materials

- Technical conditions

- Technological equipment

- CAD CAM

- The Laser Photoplotter

- CNC drilling and routing

- UV Laser drilling and routing

- Laser Tannlin TX PROi

- Direct plating

- Vyplňování otvorů | Planarizer

- Surface readjustments

- Surface finishes

- Galvanic processes

- Digital Direct Imaging

- The etching

- Solder mask and silkscreen

- Inspections of PCB

- Controlled impedance

- Multilayer lamination

- Contour fabrication

- Analytical Laboratory

- PCB Designs

- PCB assembly

- Terms and Conditions

- Preislist

- Contact

- kariéra

POOL service – principles of production

In the production of PCB prototype, film costs are often higher than costs of own board. Therefore, we have decided to introduce a new service - POOL SERVICE. This is actually the production of printed circuit boards of various types from different customers on one production panel. Customers don’t pay for film matrices, these are only used once and are not archived after the production.

This technology is worth up to about 2 pieces of PCB. Production is always a single, repetitive production is not possible. Due to the technological processes of POOL SERVICE, a type of PCB material is precisely specified:

| Material ITEQ-158 1,5mm 18um Cu ( basic ), for multilayer PCB´s material IS400 |

| Solder mask 1-2x ( green color ) |

| Service print 1-2x ( white color) – second service print for extra charge |

| Electrical testing |

| H.A.S.L. ( Laed-free HAL ) or chemical golding |

| Rectangular milling of outside edge ( used miller 2,4mm ) |

| track/gap >=150µm, driller >=0,3mm |

Buildup for 4 layers PCB : 2x 2116 + innerlayer 1,0mm 35um Cu + 2x 2116 ( total thickness 1,5mm )

Buildup for 6 layers PCB : 2x 1080 + innerlayer 0,5mm 35um Cu + 2x 1080 + innerlayer 0,5mm 35um Cu + 2x 1080 ( total thickness 1,5mm )

Multilayers PCBs in POOL service can not contain blind or buried drilling !!

Other production technologies are not possible in POOL service!

Production board of POOL service containing several customers’ boards

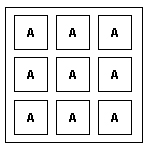

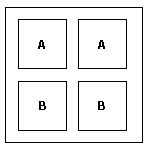

Basic types of boards in POOL service :

| PCBs of same pattern „A" delivered separately, milled on its dimension. |

|

| PCBs of same pattern "A" delivered milled on bridges ( gap between single boards is 2,4mm ) + technological area of 7mm. |

|

| PCBs of different patterns "A“, "B" ........ delivered milled on bridges ( gap between single boards is 2,4mm ) + technological area of 7mm. |

|

- Data for multipanel composed of the same or different boards should be sent already as a panelized board. Ordering multipanel composition of separate, individual types is for additional cost. Multipanels are always delivered on milled bridges!

Standard delivery time :

| 2-layers PCBs | 5 working days ( express delivery from 1 working day ) |

| 4-layers PCBs | 7 working days ( express delivery from 2 working days ) |

| 6-layers PCBs | 7 working days ( express delivery from 2 working days ) |

Optimal and recommended data structure for POOL service :

( aligned, non-mirrored and complete data for production )

| Gerber data | format : RS274-X |

| Drill data | format : Excellon |

Recommended names of input files ( other names possible for extra charge of 2 EURO)

| layer TOP | top.gbr |

| layer BOT | bot.gbr |

| layer solder mask TOP | smt.gbr |

| layer solder mask BOT | smb.gbr |

| layer service print TOP | plt.gbr |

| layer service print BOT | plb.gbr |

| inner layer 2 | in2.gbr |

| inner layer 3 | in3.gbr |

| inner layer 4 (for 6layered boards only ) | in4.gbr |

| inner layer 5 (for 6layered boards only ) | in5.gbr |

| layer outline | mill.gbr |

| layer plated milling | mill_pth.gbr |

| layer plated drilling | pth.exc |

| layer nonplated drilling | npth.exc |

Sequence of layers of conductive :

| 2-layers PCBs | TOP - BOT |

| 4-layers PCBs | TOP - IN2 - IN3 - BOT |

| 6-layers PCBs | TOP - IN2 - IN3 - IN4 - IN5 - BOT |

Data edit exceeding standard (20EURO/hour) Matched, non-mirrored and complete data in gerber 274-X and Excellon are with no extra charge. Eventual data edit are needed in gerber RS274-D, mirrored or non-matched data, solder mask layers generated by us, special technological area of the panel etc...

- Please, clearly note in your orders that you are ordering boards as POOL service, otherwise the boards will be produced in normal production and film matrices will be charged!

JOB for automatic generation of data for the POOL service from Eagle Design

JOB for automatic generation of data for the POOL service from Eagle Design

company adress :

company adress : place of business :

place of business :