- HOME

- Products

- Basic materials

- Technical conditions

- Technological equipment

- CAD CAM

- The Laser Photoplotter

- CNC drilling and routing

- UV Laser drilling and routing

- Laser Tannlin TX PROi

- Direct plating

- Vyplňování otvorů | Planarizer

- Surface readjustments

- Surface finishes

- Galvanic processes

- Digital Direct Imaging

- The etching

- Solder mask and silkscreen

- Inspections of PCB

- Controlled impedance

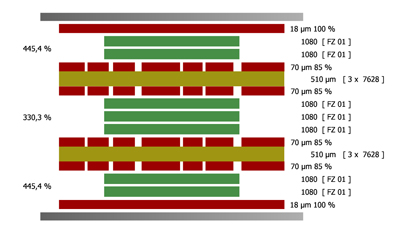

- Multilayer lamination

- Contour fabrication

- Analytical Laboratory

- PCB Designs

- PCB assembly

- Terms and Conditions

- Preislist

- Contact

- kariéra

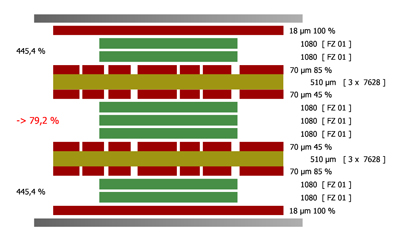

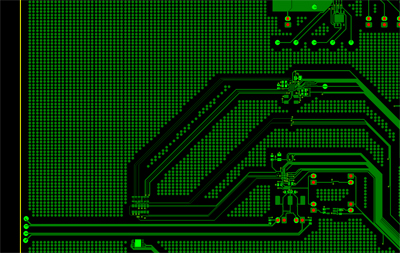

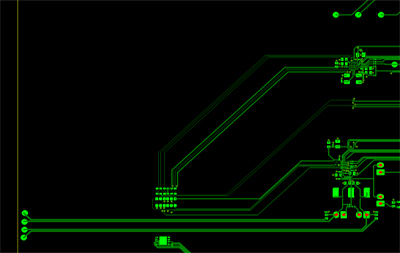

Copper balance

Copper balance on a printed circuit board is very important because unbalanced copper can cause PCB defects and errors, such as twisting, delamination, or poor electroplating of a conductive pattern that the manufacturer cannot influence.

1/ PCB twist :

- If there are unsymmetrical copper surfaces on the PCB, it can be distorted by thermal processes such as lamination, hot air leveling, or subsequent soldering wave. Correct, symmetrical distribution of conductors and copper surfaces eliminates twisting error.

2/ PCB delamination :

- The problem arises mainly from the use of thicker copper (50um or more) on cores on which the copper surface is unbalanced. Worse, where there are motifs with little copper filling. In this case, the copper surfaces need to be supplemented with a "false" area or flats to prevent overflowing of the prepreg into the motifs and subsequent delamination or interlayer short-circuit.

|

YES

|

NO

|

3/ Poor electroplating of the conductive pattern :

- For the correct setting of the galvanic process, the copper balance on the conductive layers is very important. If copper is unbalanced at the top and bottom, or even at each individual layer, overplating can occur, and lead to connected tracks or underetching. In particular, this relates to differential pairs with measured impedance values. Setting the correct galvanic process is complicated and sometimes impossible. It is therefore important to replenish the copper balance with "false" patches or full copper.

|

YES

|

NO

|

company adress :

company adress : place of business :

place of business :